The Emissions Calculator is designed for producers committed to reducing methane emissions and considering MiQ certification.

This easy-to-use tool assesses each emissions portfolio in relation to the MiQ Standard, allowing them to see their potential MiQ Certification grade and understand how their operations could improve.

Contact us at info@miq.org for questions about the tool.

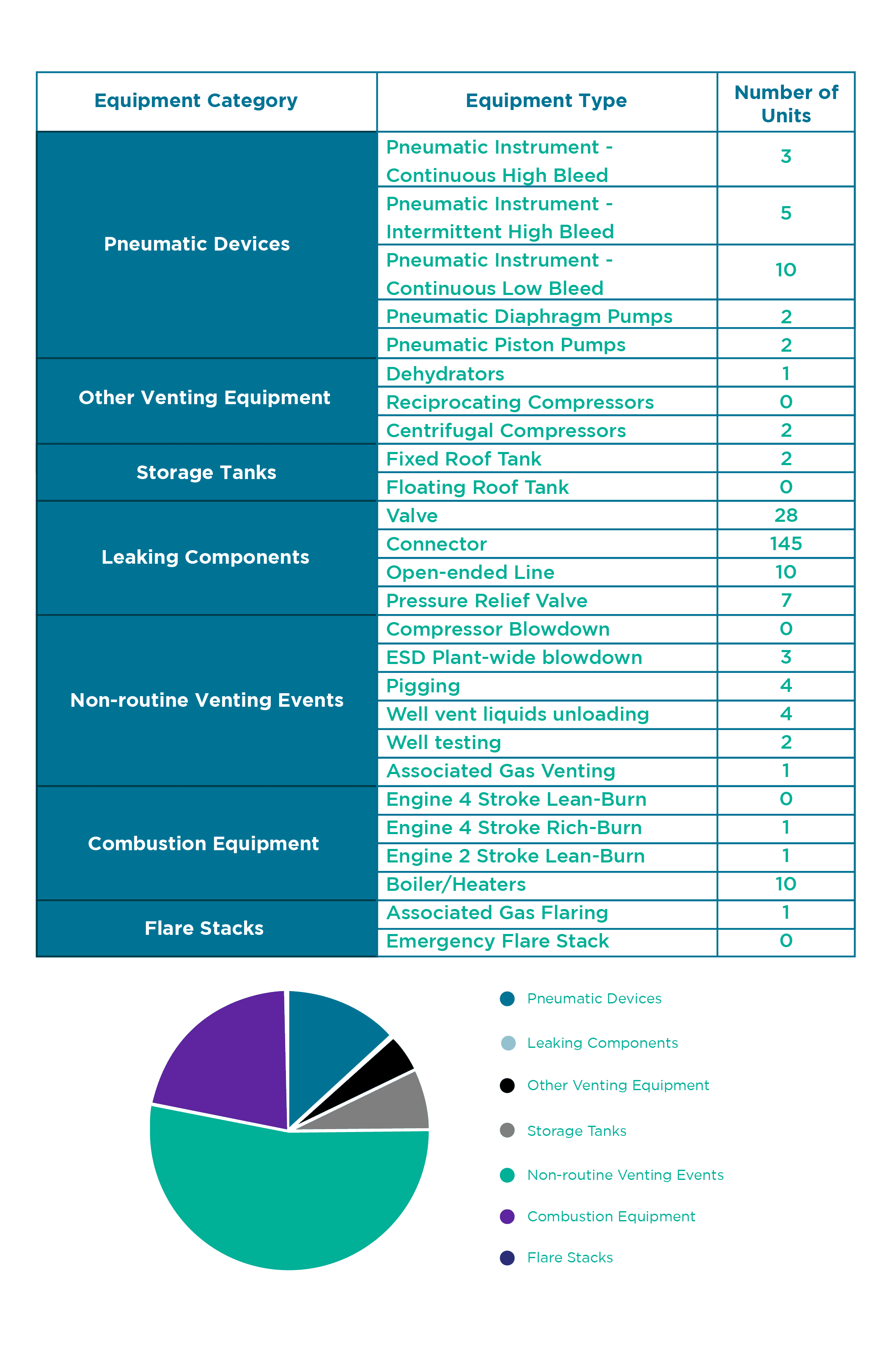

Case Study: Alberta Conventional Oil Facility

GOR = 0.69

Emissions = 256 tons CH4

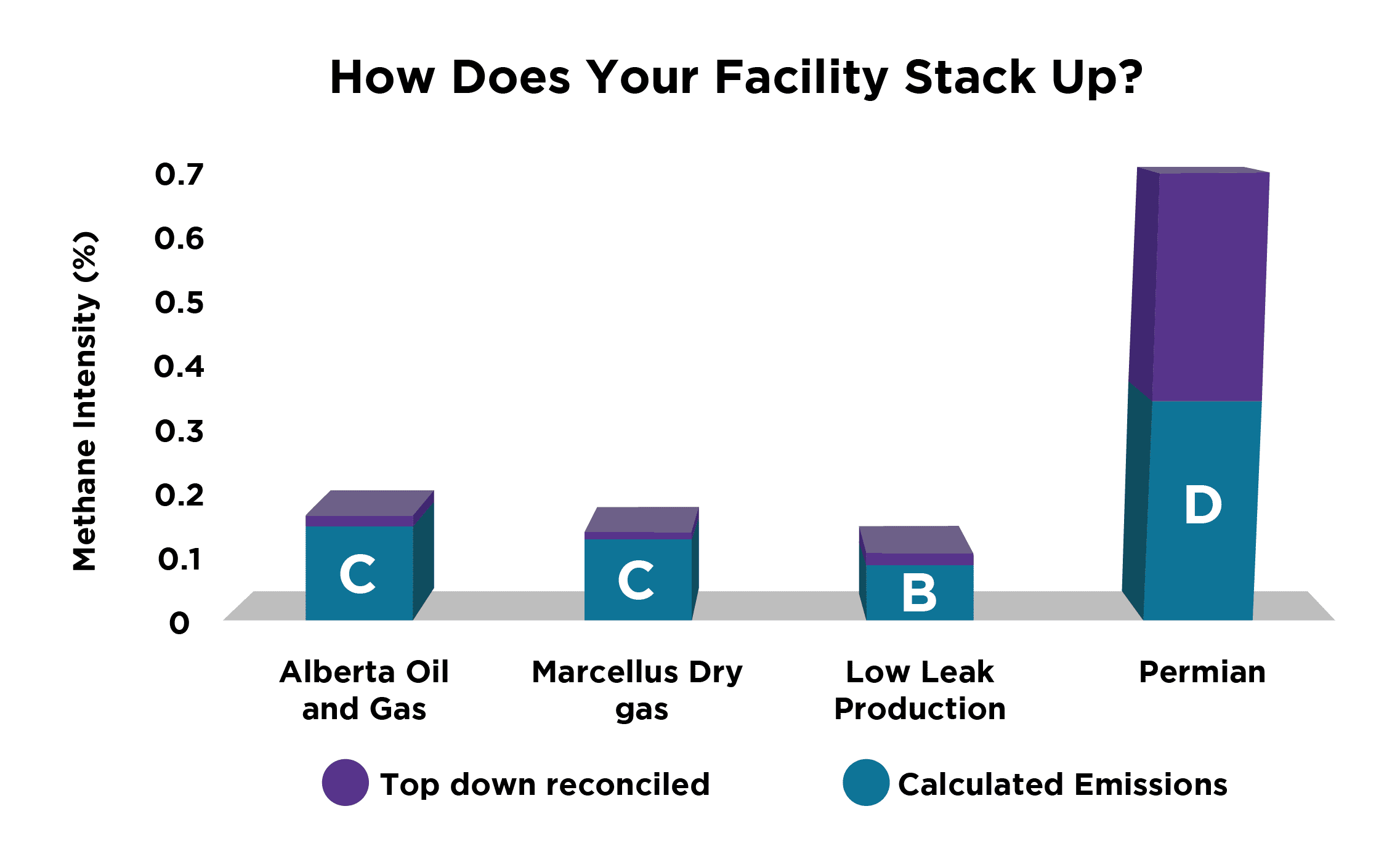

MI = 0.15%

MiQ C grade for Intensity

Alberta Regulatory Requirements:

- Fugitive leak detection and repair program (LDAR). Depending on the facility type, Directive 060 requires a minimum of annual OGI surveys up to 3x per year

- Beginning 2023 pneumatic devices need to be limited to a vent rate of 0.17m3/hr

- Beginning 2022 existing reciprocating compressor fleet average venting is limited to 0.35m3/hr/throw

- Where any single compressor venting needs to be below 5.0 m3/hr/throw

- Beginning 2022 existing centrifugal compressor venting needs to be below 10.2 m3/hr/compressor

- Compressor seal testing is required at least every 9000 hours that it is pressurized

- Total overall gas venting is limited to 15.0 103m3 of vent gas per month or 9.0 103 kg of methane per month.

- Allowable Methodology for GHG Emissions calculations AB GHG Quantification Methodologies

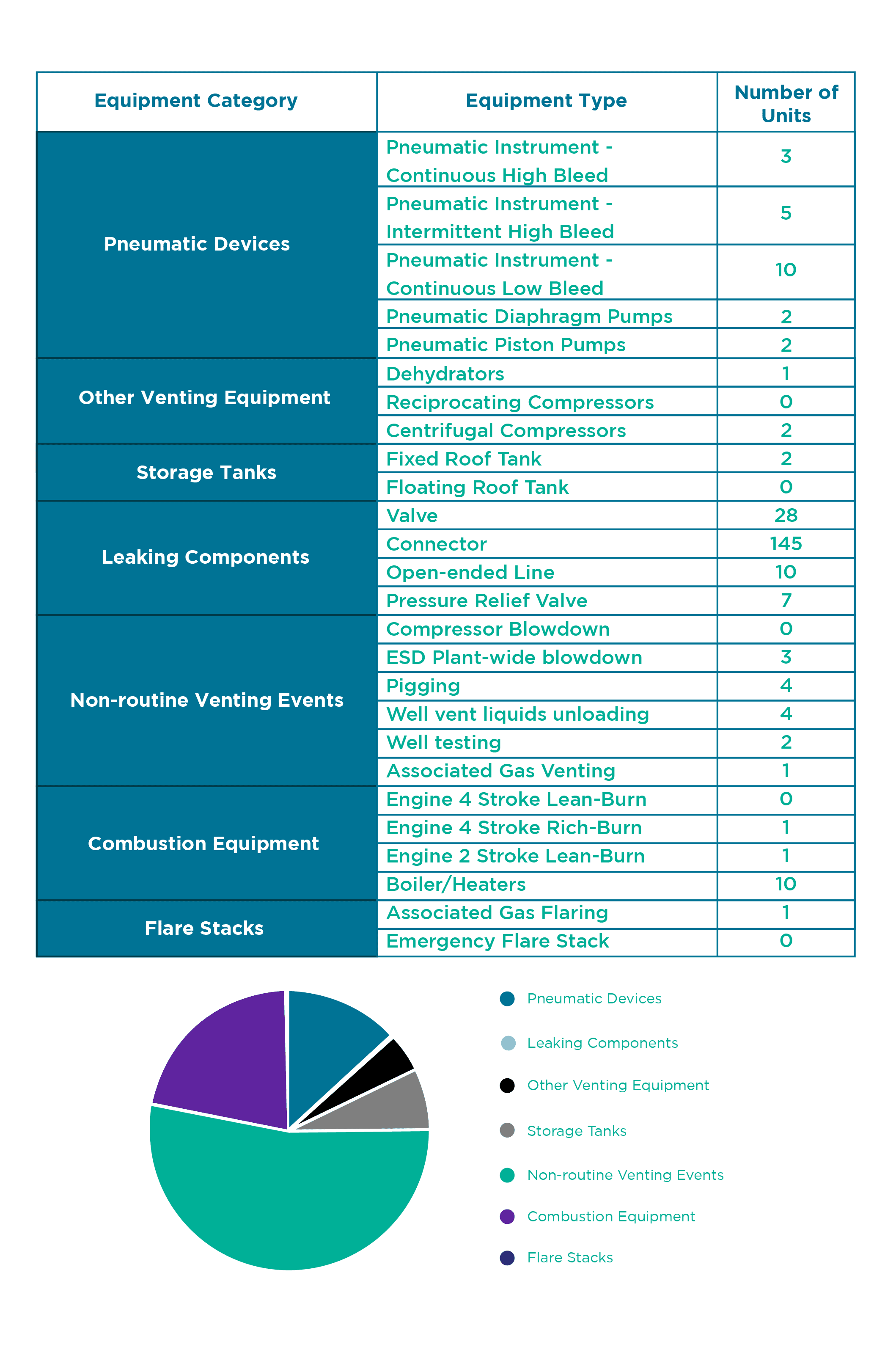

Case Study: US Eastern Marcellus Gas Facility

Emissions = 109 tons CH4

GOR = 1.0 tons

MI = 1.1%

MiQ Grade B for intensity

Local Configuration includes:

- Limiting pneumatic device venting

- Measuring compressor seal vents

- Completing required fugitive emission monitoring

- No sources from flaring or storage tanks

- Primary opportunity for reduction for electrification of combustion

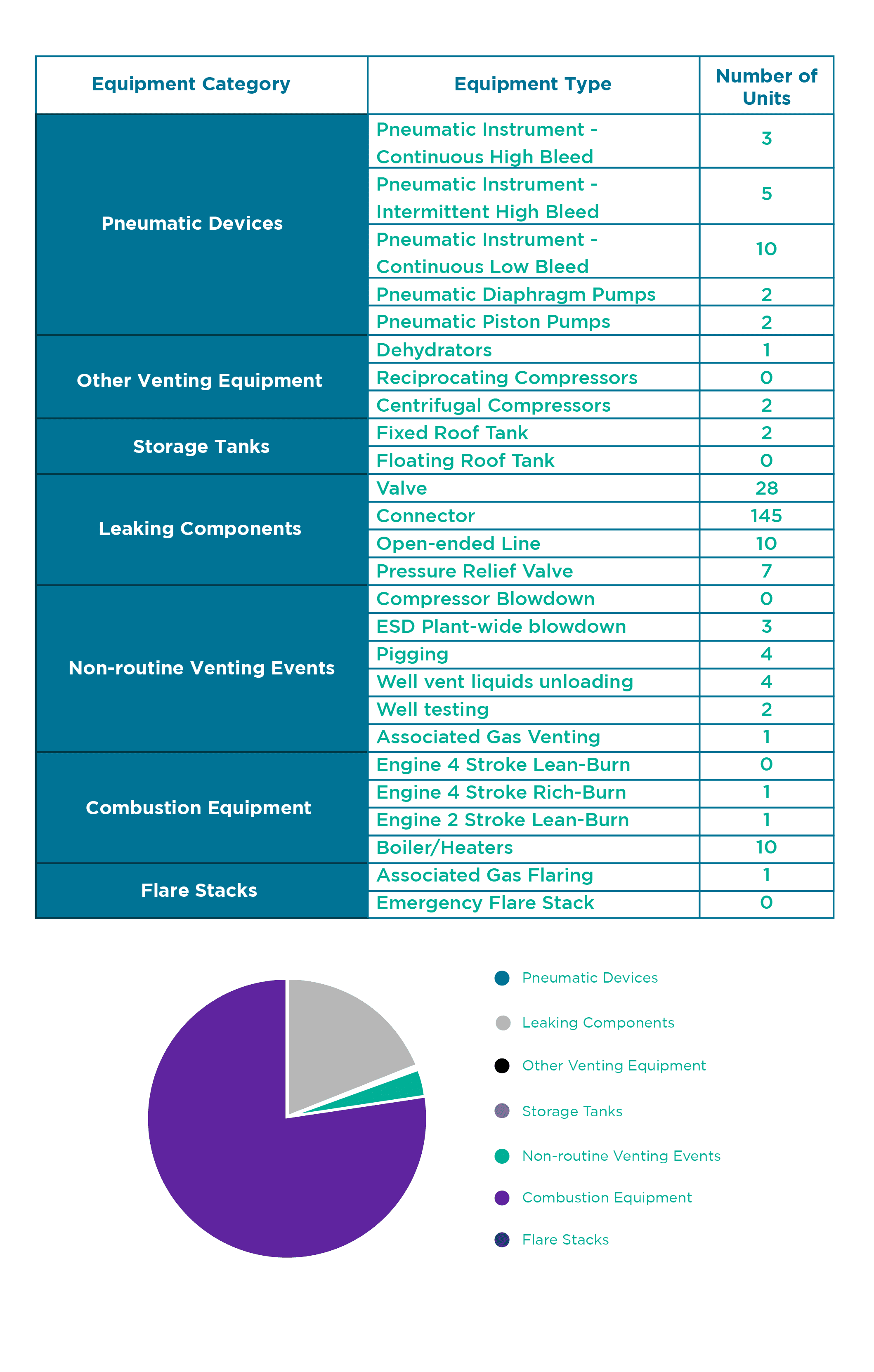

Case Study: Low leak configuration

Emissions = 72 tons CH4

GOR = 1.0

MI = 0.07%

MiQ B Grade for Intensity

Local Configuration includes:

- Pneumatics that are electrified or converted to instrument air

- Tank vented is connected to a VRU or tied into a flare or sales gas line

- Heavy or conventional oil facilities may have higher intensities due to more associated gas venting and tank venting activities where low intensity producers are more likely to be pure gas plays

Case Study: Permian Oil and Gas Facility

Emissions = 228 tons

GOR = 0.1

MI = 0.35%

MiQ D Grade for Intensity

Local Configuration includes:

- High bleed pneumatics

- No tank controls, not yet connected to VRUs

- Population counts for leaks, instead of individual leaks

- Associated gas well production leads to flaring